Introduction:

When it comes to designing reliable glucose meters, battery choice is far from trivial. For medical device manufacturers and OEM engineers, the right battery can be the difference between consistent readings and product recalls, between medical accuracy and customer complaints.

Two main chemistries dominate this field: lithium and zinc-air. Both have been used for years in portable medical devices, yet they perform very differently in terms of power delivery, stability, and life span. This guide explores how each works, what their strengths and weaknesses are, and how to select the best option for your specific glucose meter application.

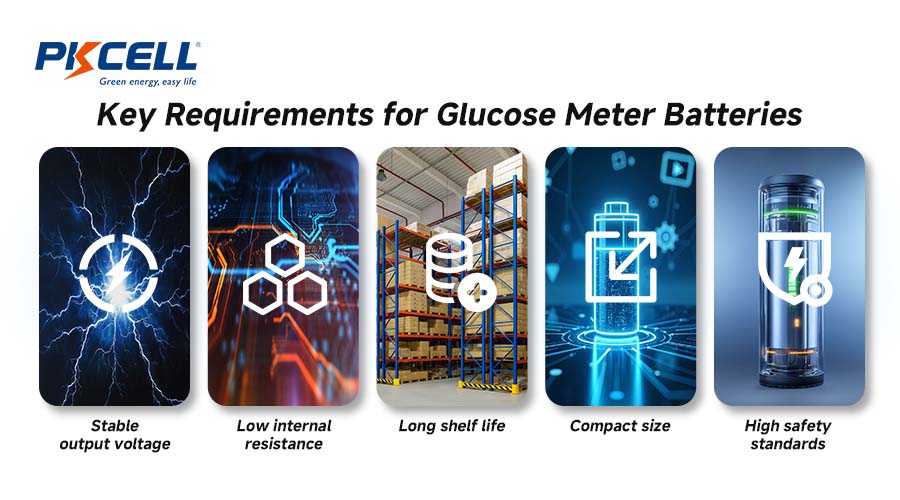

What Are the Key Requirements for Glucose Meter Batteries in Medical Devices?

Medical-grade devices such as glucose meters have very specific power requirements. Engineers must consider not only voltage and capacity, but also consistency, safety, and long-term supply. The main criteria include:

- Stable output voltage: To ensure accurate sensor readings throughout discharge.

- Low internal resistance: Prevents voltage drop during current surges.

- Long shelf life: Batteries may sit unused in packaging or storage for years before activation.

- Compact size: Fits within small enclosures without adding bulk.

- High safety standards: Compliance with medical and transportation certifications such as UN38.3, IEC 60086-4, or ISO13485.

- Batch-to-batch uniformity: For OEMs, consistency across thousands of units is essential.

Meeting these criteria narrows the field down to two main contenders — lithium coin cells and zinc-air batteries.

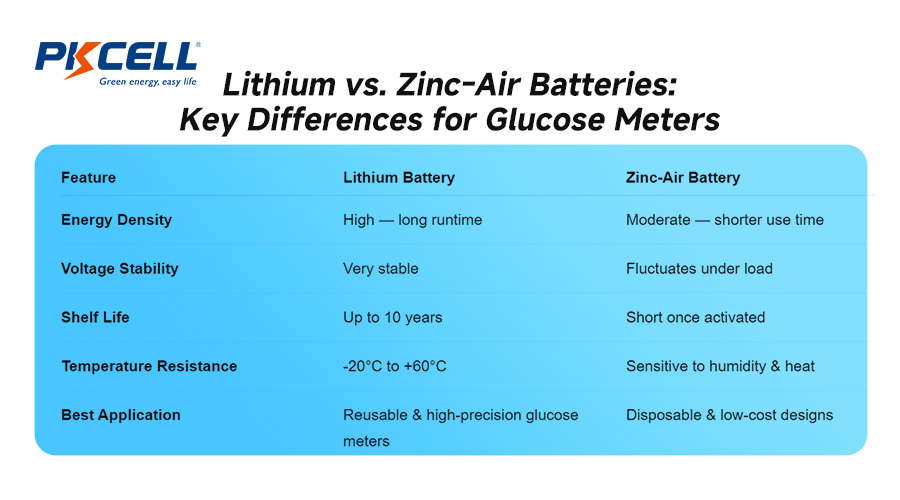

How Do Lithium and Zinc-Air Batteries Compare in Performance?

Energy Density and Runtime

Lithium batteries offer some of the highest energy densities of any primary chemistry — typically around 200–300 Wh/kg. This means they can power a glucose meter for months or even years, depending on usage frequency. For devices that require long shelf life and infrequent replacement, lithium clearly has the edge.

Zinc-air batteries, while excellent for hearing aids and other low-drain applications, generally have lower energy density. They rely on oxygen from the air as a reactant, which limits their total stored energy once exposed.

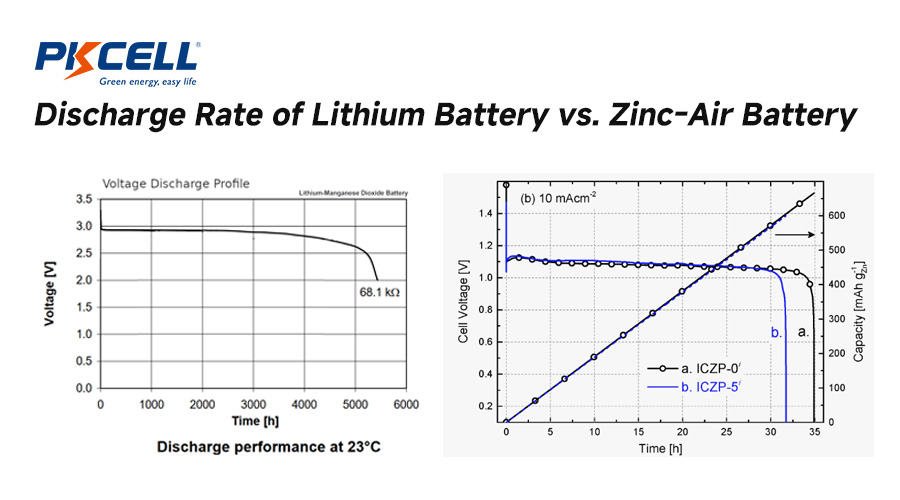

Discharge Rate and Stability

Lithium coin cells provide stable voltage output throughout most of their discharge curve. This stability ensures consistent sensor readings even when battery life is nearing its end.

Zinc-air cells, on the other hand, are designed for very low continuous current draw. If a glucose meter requires bursts of power — such as during data transmission or backlit display activation — zinc-air cells may show voltage dips, which can interfere with readings.

For OEM engineers designing devices with digital displays or Bluetooth connectivity, lithium’s stability becomes crucial.

Shelf Life and Storage

Lithium cells can remain operational for up to 10 years when stored properly, thanks to their low self-discharge rate (typically less than 1% per year).

Zinc-air batteries are activated by removing a seal that exposes them to air. Once unsealed, they begin to dry out and lose capacity, regardless of use. This makes them less suitable for products requiring long pre-sale or storage periods.

Temperature Resistance

Environmental performance is another key factor.

- Lithium batteries can operate from -20°C to +60°C, maintaining voltage stability even under fluctuating ambient temperatures.

- Zinc-air batteries, however, are more sensitive to humidity and temperature changes. High humidity can block air flow to the cathode, while dry air can cause premature drying and capacity loss.

If your glucose meters are distributed globally or used in varying climates, lithium batteries provide greater reliability.

Which Battery Chemistry Is Better for Mass-Produced Glucose Meters?

The answer depends on the design philosophy of your glucose meter.

- For high-end reusable glucose meters:

- Lithium coin cells (e.g., CR2032, CR2450) are ideal. They provide long shelf life, consistent voltage, and are easy to source for large production runs.

- For disposable or single-use meters:

- Zinc-air batteries may still make sense. Their low cost and steady discharge at minimal current loads suit temporary medical devices.

In short, lithium batteries win in terms of durability, reliability, and engineering simplicity — making them the preferred choice for most OEM and medical device manufacturers today.

What Should B2B Buyers Look for in a Glucose Meter Battery Supplier?

Selecting the right supplier is just as important as choosing the right chemistry. B2B buyers should prioritize:

- Medical-grade production standards — Look for ISO13485 or ISO9001 certification.

- Traceability — Batch-level QC reports and material traceability.

- Custom packaging and labeling — Supports private branding and compliance.

- Technical support — Engineering teams who can assist with voltage matching and discharge testing.

- Stable supply chain — Consistent bulk availability and export documentation.

Building a relationship with an experienced lithium battery manufacturer ensures not only quality but also a long-term partnership for medical device development.

Recommended Lithium Battery Models for Glucose Meters

| Model | Voltage | Capacity | Key Features | Certification |

|---|---|---|---|---|

| CR2032 | 3V | 210mAh | Stable discharge curve, compact size | IEC, UN38.3 |

| CR2450 | 3V | 600mAh | Extended runtime | IEC, UL |

| BR2032 | 3V | 220mAh | High-temperature tolerance | RoHS, UN38.3 |

PKCELL offers all these models with consistent bulk supply, OEM labeling options, and full UN38.3 and IEC certification for international transport and medical use.

Quote for PKCell Bulk Lithium Button Cell Battery

FAQs About Glucose Meter Batteries

Q1: Can lithium batteries safely replace zinc-air batteries in glucose meters?

Yes, as long as the device’s voltage tolerance supports 3V lithium cells. They offer more stable performance, especially for digital or connected glucose meters.

Q2: What certifications should a glucose meter battery have?

Key certifications include UN38.3 (transport safety), IEC 60086-4 (safety of lithium systems), and ISO13485 for medical manufacturing compliance.

Q3: Are rechargeable lithium batteries suitable for glucose meters?

Generally not. Most glucose meters are designed for single-use or long-lasting primary batteries to ensure user safety and regulatory simplicity.

Q4: How long can glucose meter batteries be stored before use?

Lithium coin cells can be stored for up to 10 years under controlled temperature and humidity, while zinc-air cells must be used shortly after activation.

Q5: What’s the best way to source glucose meter batteries in bulk?

Partner with a certified B2B lithium battery supplier offering bulk packaging, export documentation, and ongoing technical support for integration.

Post time: Nov-05-2025