The lithium thionyl chloride battery is a long-lasting and trustworthy power source for the IoT industry, especially smart meters and subsea sensors. However, its high energy density comes with unique safety profiles that every engineer and sourcing manager must understand.

This guide provides a deep dive into the safety mechanisms, regulatory compliance, and handling protocols for li socl2 chemistry.

The Chemistry of Stability: Understanding Li-SOCl2

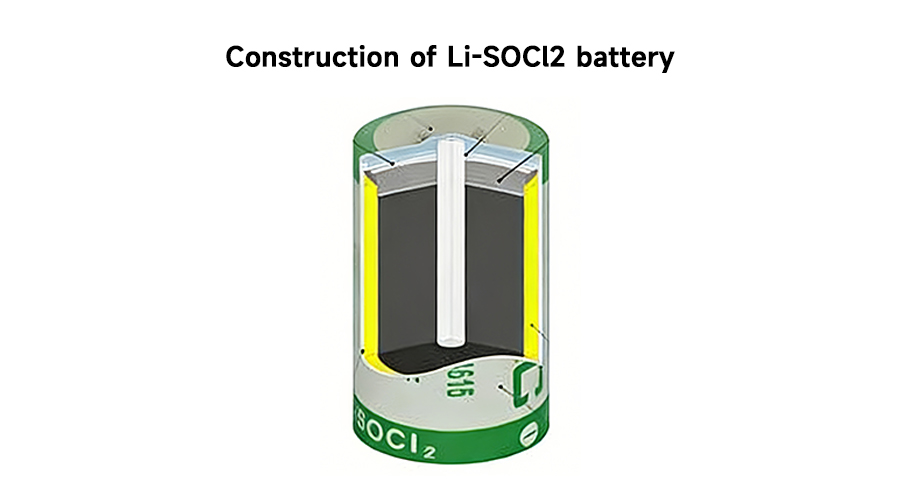

The li socl2 system is a primary (non-rechargeable) chemistry that utilizes a liquid cathode. This unique structure allows for a very high energy density but requires sophisticated hermetic sealing to prevent the release of toxic thionyl chloride vapors.

One of the most critical safety features of a li socl2 3.6 v battery is passivation, which is the formation of a thin film of lithium chloride (LiCl) on the lithium anode. The passivation will cause a voltage delay, but it is actually a vital safety mechanism that prevents internal self-discharge and thermal runaway during long-term storage.

2025 Regulatory Compliance: IEC & IATA Updates

Safety is not only an engineering goal, but also a legal requirement. In 2025, several key regulations have been updated to reflect the evolving global supply chain:

- IEC 60086-4:2025 (6th Edition): This new standard has introduced stricter definitions for “leakage” and “venting.” It also revised the overdischarge test criteria, specifically for cells like the ER14505, to ensure they remain stable even when accidentally drained in series.

- IATA 66th Edition (2025): For distributors shipping a lisocl2 battery by air, the 2025 DGR (Dangerous Goods Regulations) maintains that UN3090 lithium metal batteries are forbidden on Passenger Aircraft. They must be shipped as “Cargo Aircraft Only” (CAO) and comply with Packing Instruction 968.

- UN38.3 Certification: Every lithium socl2 battery intended for transport must pass the UN38.3 tests, including altitude simulation, thermal testing, vibration, and mechanical shock.

Quote for Bulk LiSoCl2 Battery With UN38.3

Safety Features Comparison Table

| Feature | Bobbin-type (ER Series) | Spiral-type (ERM Series) | Safety Impact |

| Energy Density | Extremely High | Moderate | Bobbin is safer for low-rate discharge. |

| Internal Surface Area | Small | Large | Spiral types require higher safety venting specs. |

| Short-Circuit Risk | Low | Moderate | Spiral cells generate heat faster if shorted. |

| Venting Mechanism | Standard | High-Pressure Vent | Prevents casing rupture during abuse. |

| Operating Temp | -55°C to +85°C | -55°C to +85°C | Higher stability at extreme temperatures. |

Best Practices for Handling and Storage

To ensure the longevity and safety of your lithium socl2 battery inventory, manufacturers and distributors should follow these 2025 industry protocols:

- Temperature Control: Store batteries in a cool, dry environment (preferably below 30°C). High temperatures accelerate passivation growth and increase internal pressure.

- Mechanical Protection: Avoid crushing or piercing the cells. Even a small puncture can expose the li socl2 electrolyte to atmospheric moisture, creating corrosive hydrochloric acid (HCl) and sulfur dioxide (SO2).

- Insulation: Ensure terminals are protected during bulk transport. A simple short circuit of a li socl2 3.6 v battery can lead to rapid heating within seconds.

- No Recharging: LiSoCl2 batteries are non-rechargeable batteries. The temptation to charge the batteries can lead to an explosion.

- Separation: Separate different brands of batteries while storing the batteries, and put used batteries and new batteries apart.

Why Partner with PKCELL?

PKCELL is a professional B2B battery manufacturer specializing in high-performance primary lithium solutions. Our lisocl2 battery lineup, including the widely used ER14250, ER14505, ER34615, and ER26500, is engineered with safety as the primary directive.

Our Safety Commitment: We provide full documentation for UN38.3 compliance to ensure your shipments reach their destination without delay.

Our Customized Battery Solution: We provide customized terminals and hybrid capacitors to meet the specifications of your products.

FAQs

Will Lithium thionyl chloride batteries explode?

While a lithium thionyl chloride battery is highly stable under normal operating conditions, it can explode or vent violently under “abuse conditions.” These include heating the cell above 100°C (unless it is a specialized high-temp model), physical crushing, forced recharging, or external short-circuiting.

How do you “wake up” a passivated Li-SOCl2 battery?

If a li socl2 3.6 v battery has been in storage for over 6 months, it may show a “voltage delay.”5 To wake it up, apply a small “depassivation load” (a specific resistor) for a few minutes. This safely breaks down the LiCl layer without damaging the cell.

Can I replace an alkaline battery with a 3.6V Li-SOCl2 cell?

No. Standard alkaline batteries are 1.5V, whereas a lithium socl2 battery is 3.6V.6 Using it in a device not designed for the higher voltage will likely damage the electronics.

Post time: Dec-26-2025